ABSTRACT

This paper deals with the recent

evolution in SI engines, that is, GDI technology along with turbocharging and

emission control.

Gasoline direct injection (GDI)

engine technology has received considerable attention over the last few years

as a way to significantly improve fuel efficiency without making a major shift

away from conventional internal combustion technology. In many respects, GDI

technology represents a further step in the natural evolution of gasoline

engine fueling systems. Each step of this evolution, from mechanically based

carburation, to throttle body fuel injection, through multi-point and finally

sequential multi-point fuel injection, has taken advantage of improvements in

fuel injector and electronic control technology to achieve incremental gains in

the control of internal combustion engines. Further advancements in these

technologies, as well as continuing evolutionary advancements in combustion

chamber and intake valve design and combustion chamber flow dynamics, have

permitted the production of GDI engines for automotive applications.

GASOLINE DIRECT INJECTION

Continued drawbacks from the conventional

carburetor have tended to develop new techniques in SI engines. The consistent

draw backs are the higher fuel consumption, greater emissions & lower

output, GDI is the recent technology which is becoming a dominant solution over

these limitations.

Direct injection has started to get a

grip on the petrol engine market and today we have really entered the age of

gasoline direct injection. The demand for more efficient engines offering

reduced fuel consumption but maintaining high output has been behind the evolution

of latest GDI engines. GDI engines are characterized by injection of fuel at

high pressure directly into the combustion chamber by specially developed

injectors. During the induction stroke the air flows into the cylinder. The

beginning of the end of intake manifold injection technology is marked by the

introduction of GDI engines. The GDI engine technology has received

considerable attention over the last few years as a way to significantly

improve fuel efficiency without making a major shift away from conventional

internal combustion technology.

GDI technology has potential

applications in a wide segment of automotive industry. It is attractive to two

stroke engine designer because of the inherent ability of in cylinder injection

to eliminate the exhaust of uncombusted fuel during the period of overlap in

intake and exhaust valve opening. The greatest fuel efficiency advantages of

GDI can be realized in direct injection stratified charge lean combustion

applications, significant fuel savings can be achieved even under stochiometric

operation.

Use of gasoline direct injection (GDI) can reduce charge-air temperature while

allowing for higher compression ratios.

This has the effect of reducing the potential for detonation yet

increasing gasoline engine efficiency. Instead of fuel and air mixing prior to

entering the cylinder as with typical fuel injection, GDI uses a high-pressure

injector nozzle to spray gasoline directly into the combustion chamber. An example of a GDI system is shown in Figure. One advantage of GDI is that as the fuel

vaporizes, it absorbs energy from the charge.

This “cooling effect” lowers the temperature of the air in the cylinder,

thereby reducing its tendency to detonate.

Figure 1. A gasoline direct injection (GDI) system

GDI can also increase cylinder emptying during the exhaust

stroke.

П] MAJOR OBJECTIVES OF GDI ENGINE

1. Ultra

low fuel consumption.

2. Superior

power to conventional MPFI engine.

1. The

difference between new GDI and current MPFI

For fuel supply,

conventional engines use a fuel injection system, which replaced the

carburetion system. MPFI or Multi-Point

Fuel Injection, where the fuel is

injected to each intake port, is currently the one of the most widely used

systems. However, even in MPFI engines there are limits to fuel supply response

and the combustion control because the fuel mixes with air before entering the

cylinder. Now day’s companies are developing an engine where gasoline is

directly injected into the cylinder as in a diesel engine, and moreover, where

injection timings are precisely controlled to match load conditions. The GDI

engine achieved the following outstanding characteristics.

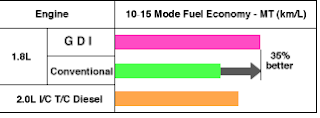

Fig

shows comparison of GDI with other fuel injection systems.

Fig.

Transition of fuel supply system

The GDI technology have assisted the engine to acquire

certain outstanding features such as

1] Extremely precise control of fuel supply to

achieve fuel efficiency that approaches to that of diesel engines by enabling

combustion of ultra lean mixture.

2] Very efficient intakes and relatively

higher compression ratio.

2. MAJOR SPECIFICATIONS

PARAMETER

|

GDI

|

CONVENTIONAL MPFI

|

Compression ratio

|

12

|

10.5

|

Combustion chamber

|

Curved -top piston

|

Flat -top piston

|

Intake port

|

Upright straight

|

Standard

|

Fuel system

|

In cylinder direct injection

|

Port injection

|

Fuel pressure(MPa)

|

50

|

3.3

|

Fuel injection allows the fuel to burn completely in the cylinder, so

that, unburnt charge would be negligible which lacks any knocking or

precombustion in the engine. Higher compressions can be possible which will

increase power output, thermal efficiency without knocking.

3. Technical

features

- Upright straight intake ports for optimal airflow control in the cylinder

- Curved-top pistons for better combustion

- High pressure fuel pump to feed pressurized fuel into the injectors

- High-pressure swirl injectors for optimum air-fuel mixture

1. Lower fuel

consumption and higher output

A] OPERATING MODES IN

GDI ENGINES

1] Stratified

operation mode

The engine offers highest amount of

fuel savings in the stratified lean operation mode with a large amount of

excess air. As the fuel injected is small in quantity control over its

injection timing is very important otherwise homogenization of the same would

lead to no or very poor combustion. Therefore the fuel air mixture is

concentrated by strategic injection no earlier than last third of the upwards

movement of the piston so that the fuel will be concentrated exactly around the

spark plug. The air fuel ratio at this mode is 30 to 40.

As there is

no dependency of fuel injection with throttle opening the throttle remains wide

open during the induction stroke, allowing the maximum air with proper

circulation. The charge stratification allows engine to burn total cylinder

mixtures with a much high concentration of air than conventional engines. The

air fuel ratio can be as high as 55:1. During stratified charge operation, the

injectors meter the fuel mass so precisely that unthrottled operation is

possible which reduces pumping effect and lowers fuel consumption. Stratified

mixture greatly decreases air fuel ratio without leading to poorer combustion.

In addition, ignition and combustion occur centrally in the combustion chamber,

surrounded by an insulating air cushion that reduces heat dissipation at the

cylinder wall, thus improving the efficiency. The characteristic-controlled

cooling also somewhat increases the economy; during underloads, it lets the

coolant temperature increase to 110 degrees Celsius, thus improving the

efficiency of the engine. However, the especially economical stratified lean

operation mode functions only in the case of underloads and low speeds (up to

3000 rpm). At higher speeds, the time is not sufficient to optimally prepare

the fuel, which is injected very late during the stratified lean operation

mode, and to control the emissions.

2]

Homogenous operation mode

When the GDI engine is operating

with higher loads or at higher speeds, fuel injection takes place during the

intake stroke. This optimizes combustion by ensuring a homogeneous, cooler

air-fuel mixture that minimized the possibility of engine knocking. If the driver requires increased engine performance,

the engine controller automatically switches to the homogenous operation mode,

with an evenly distributed fuel-air mixture in a stoichiometric relationship

(lambda equals 1). Now, the fuel is injected into the air in the intake in time

with the intake of air so that a homogenous, easily combustible fuel-air

mixture forms within the entire combustion chamber.

This is not required at higher

engine loads, where the switch valve opens so that the air can flow into the

combustion chamber without any impediments. Another factor that reduces

consumption in the homogenous operating mode is that the engine has a higher

efficiency than conventional petrol engines with intake manifold injection due

to higher compression.

3] Homogenous lean operation mode

The third operating mode of the engine at

higher loads and speeds where stratified operation is no longer possible is the

homogenous lean operating mode. In terms of performance characteristics, it can

be said that this operating mode forms a belt between the stratified operation

and the homogenous operating modes. In order to increase the turbulence and

thus the inflammability of the lean mixture, injection and combustion run in a

manner similar as in the homogenous operation mode, with the difference that

more air is mixed in than is required for combustion. As a result, fuel

consumption can be reduced.

B] The GDI engines

foundation technologies

1] In cylinder air flow

The GDI engine has

upright straight intake ports rather than horizontal intake ports used in

conventional engines. The upright straight intake ports efficiently direct the

airflow down at the curved-top piston, which redirects the airflow into a

strong reverse tumble for optimal fuel injection.

2]

Fuel Spray

Newly developed high-pressure swirl injectors provide the

ideal spray pattern to match each engine operational modes. And at the same

time by applying highly swirling motion to the entire fuel spray, they enable

sufficient fuel atomization that is mandatory for the GDI even with a

relatively low fuel pressure of 50kg/cm2.

3] Piston shape

2. Realization

of lower fuel consumption

(1) Basic Concept

In conventional MPI engines, there were limits to the mixtures leanness

due to large changes in combustion characteristics. However, the stratified

mixture of the GDI enabled greatly decreasing the air-fuel ratio without

leading to poorer combustion. For example, during idling when combustion is

most inactive and unstable, the GDI engine maintains a stable and fast

combustion even with an extremely lean mixture of 40 to 1 air-fuel ratio.

(3) Vehicle Fuel Consumption

Fuel Consumption

during Idling

The GDI engine maintains stable combustion even at low idle

speeds. Moreover, it offers greater flexibility in setting the idle speed.

Compared to conventional engines, its fuel consumption during idling is 40%

less.

Fuel Consumption during Cruising Drive

At 40km/h,

for example, the GDI engine uses 35% less fuel than a comparably sized

conventional engine.

Fuel Consumption in City Driving

The GDI

engine used 35% less fuel than comparably sized conventional gasoline engines.

Moreover, these results indicate that the GDI engine uses less fuel than even

diesel engines.

Emission

Control

Unregulated emissions such as

benzene, 1-3butadiene, formaldehyde, and acetaldehyde are the vehicular

hydrocarbon emission components coming out from the GDI engines, which will be

targeted near future. Hcs are removed by a catalyst at normal operating

conditions, but the conversion efficiency is low at the cold start conditions.

Previous efforts to burn a lean

air-fuel mixture have resulted in difficulty to control NOx emission. However,

in the case of GDI engine, 97% NOx reduction is achieved by utilizing high-rate

EGR (Exhaust Gas Ratio) such as 30% that is allowed by the stable combustion

unique to the GDI as well as a use of a newly developed lean-NOx catalyst.

3.

Realization of Superior

Output

(1)

Basic concept

Compression

ratio and a highly efficient air intake system, which result in improved

volumetric efficiency.

Improved

Volumetric Efficiency

The upright straight intake ports

enable smoother air intake. And the vaporization of fuel, which occurs in the

cylinder at a late stage of the compression stroke, cools the air for better

volumetric efficiency.

Increased Compression Ratio

The cooling of air inside the

cylinder by the vaporization of fuel has another benefit, to minimize engine

knocking. This allows a high compression ratio of 12, and thus improved

combustion efficiency.

(2) Achievement

Engine performance

Compared to conventional MPI engines

of a comparable size, the GDI engine provides approximately 10% greater outputs

and torque at all speeds.

Vehicle Acceleration

In

high-output mode, the GDI engine provides outstanding acceleration.

The following chart compares the performance of the GDI engine with a conventional MPI engine.

The following chart compares the performance of the GDI engine with a conventional MPI engine.

GDI WITH

TURBOCHARGING

In current turbocharged applications, the

intake and exhaust valves are never open simultaneously. Unfortunately, lack of

any valve overlap allows combustion

gasses to remain in the cylinder after the exhaust stroke, which is a detriment

to the next combustion process and can possibly increase NOX

emissions. In GDI engines, though, the intake charge is air only—not an

air-fuel mixture. This means that both

intake and exhaust valves can be open at the end of the exhaust stroke and that

fresh air can be used to flush out the cylinder.

Another recent

innovation in turbocharger design that can further aid cylinder emptying during

the exhaust stroke is the concept of twin-scroll turbine

housing. Twin-scroll turbine housing

serves to prevent pressure-wave interaction of the exhaust flows. Engines with an even number of cylinders,

especially four-cylinder engines, frequently have a problem with exhaust

pressure-waves from cylinders just beginning the exhaust stroke interacting

with other cylinders that are nearing the end of the exhaust stroke. By using

typical single-inlet turbine housing, approximately ten percent of the

combustion gas remains in the cylinder after each exhaust stroke. Twin-scroll turbine housing, like that

pictured in Figure, creates two separate inlets to the turbine section. Each inlet combines the exhaust flows from

cylinders that are on different strokes in the cycle. Utilization of twin-scroll turbine housing

significantly reduces the pressure-wave interaction between the cylinders,

helping empty the cylinders of exhaust gasses more completely.

Figure 16. This is a picture of a turbocharger

with twin-scroll turbine housing. Notice

the dual inlets that allow the separation of exhaust from interacting cylinders

Gasoline for GDI engine

The GDI engine is persisting

fundamental drawback with sulfur content in the gasoline, which increases NOx

emissions during stratified operation mode. The sulfur content in the gasoline

should be restricted to 5ppm compared to 338ppm present actually in the gasoline.

SUMMERY

& CONCLUSION

SUMMARY

GDI

though developed long before in 1930s, its configuration and the new electronic

control are among the top of the new inventions. GDI on the way to satisfy

today’s fuel saving requirements and increasing environmental demands.

Flexibility to adopt changing vehicle requirements is the key benefit of the

GDI which separate it from other conventional engines.

Emissions coming out from the burning of fuel at low temperature during

stratified operation mode are the major concerns ahead. Turbocharging and new

emission control techniques can be used for their subsequent regulation and

control.

All

the major car manufactures are now shifting towards GDI and MPFI soon is

replaced by it. GDI engines will spread quickly in the countries having strict

standards about pollution control and the fuel quality being used.

CONCLUSION

From this paper it can be concluded that GDI helps improving fuel

savings, thermal efficiency pioneered by its different operating modes.

Restriction of sulfur to 5ppm in gasoline is the key requirement for emission

control. Like

the all the fuel injection systems that have come before it, the new direct

injection engines will still require replacement parts and will likely suffer

from similar injector woes that plague today's engines. In fact, direct

injection injectors may prove to be even more troublesome than today's indirect

injectors because they're exposed directly to the heat of combustion.